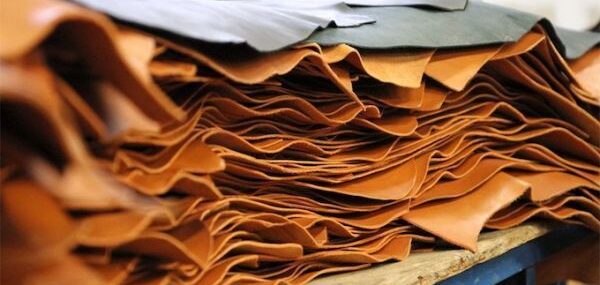

Italian leather, like Italian sports cars or suits, screams luxury. Other than the quality of the product, the idea of wearing shoes or having a belt or a wallet made of Italian leather comes with a certain oomph factor. Which is why, perhaps, every businessman involved in the leather industry in Pakistan is constantly raving about how Pakistan produces the best quality leather after Italy.

The claim, which sounds like a tall one at first, is not without substance. Sporting leather apparel from Pakistan may not have the same appeal and brand equity that its Italian competitor does, but leather products from Pakistan constantly hold up their own quality wise on the global market.

For starters, most of the leather produced here is vat-dyed instead of the spray-dyed stuff that is more commonly available, which means it keeps its colour for longer. The frequency with which American bikers and biking enthusiasts on Harley Davidson forums extol the virtues and affordability of Pakistani leather is amusingly high. And if you egg local manufacturers on enough, they will eventually break and say their leather is the best in the world, and the Italians are simply getting by on brand value.

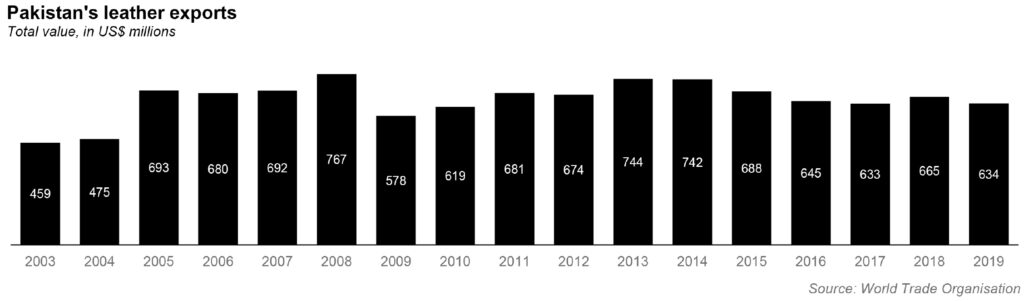

Unsurprisingly enough, since it is a rare quality product that Pakistan is capable of producing, it is one of our top exports. The second largest export oriented industry in the country, Pakistan is not even among the top 10 leather producing countries in the world, but its product does offer high quality.

One of the reasons for this has been the annual influx in hides that happens after the Eid-ul-Adha holiday. Larger animals being sacrificed instead of smaller animals that are usually slaughtered in livestock farming means larger hides, which in turn produce higher quality products. But with a less noisy Eid with fewer animals expected because of the coronavirus pandemic, the industry is bracing for impact.

But the coronavirus, while devastating, is not solely responsible for the state of one of Pakistan’s major export products. As with most promising industries here, the main reason for the crisis in the leather industry has to do with not modernising the industry on time by shying away from adopting changing trends. While Pakistani leather is a hot product all over the world including in Germany, France, United Kingdom, Italy, Spain, the Netherlands, Hong Kong, Denmark, Canada, Belgium and Dubai, lower prices offered by India, Japan, Taiwan and South Korea are giving Pakistan stiff competition.

Overhead costs, pending payments, a global pandemic, and aggressive competition and a shaky standing in the eyes of the international community are holding Pakistan’s leather industry back from achieving its full potential. Profit, takes a look at whether one of our major exports might be slipping through the cracks, right under our noses.

The state of the industry

The year 2020 was supposed to be a good one for the leather industry. The past few years had been rough, with the biggest complaint being that overhead costs were too high to remain competitive. “The overhead costs of our competitors, including India, Bangladesh and Vietnam, are shockingly lower than ours,” says Sheikh Afzal Hussain, the Chairman of the Pakistan Tanners Association (PTA).

“Gas, electricity bills, sales taxes on raw materials and duties on imports of chemicals are creating hitches for the industry, which makes the price of our leather more expensive in the international market and reduces demand,” he says. It was because of these reasons that the leather industry had been facing what can only be called a recession for the past few years.

However, according to the PTA, things were just beginning to improve. In 2019, the association had predicted that the first quarter of 2021 would prove to be very good for the industry, especially since the government was keen on being export oriented to bring the balance of payments in equilibrium. That is when Covid-19 struck, and like all other industries, the leather industry also took a hit.

“After the pandemic, there were only more problems. The increase in freight charges from Rs100-150 to Rs1,000 per kilogram after Covid-19 is also creating extreme difficulties for us,” said Sheikh Hussain. “The government does not seem to have any policies for the betterment of the leather industry. There are many statements but no implementation.”

The tanners association has demanded that the government look into their problems before their industry collapses completely. With 800 tanneries across the country and production numbers of around 13.0 million hides and 47.4 million hides per annum (2015-16), the industry employs more than 500,000 people directly and indirectly (2009-2010). And the demand, at this point, is no longer a subsidy or a handout, but a significant reduction in overhead costs. “If the government agrees to our demands, our exports will increase by 50% in the next few years,” said a statement from the association.

The pattern of the current government is one that most people in the industry are in agreement with. That with the Pakistan Tehrik-e-Insaf (PTI) in power in the center, they had been looking forward to a good year in 2020, but that the pandemic along with government policies had made them hopeless.

“We thought 2020 would be our year,” Syed Nadeem Abbas, chairman of Pakistan Leather Garments Manufacturers and Exporters Association (PLGMEA), concurs. “There was huge demand for leather products from the fashion industry, but Covid-19 has affected 60% to 70% of that demand from the international market. These sales were supposed to take place in the winters, but it never happened after the lockdown. The whole process of orders and manufacturing also stopped because the time factor counts a lot in this business.”

These statements are all expressions of frustration and point towards an inability to adapt to crises and a desire to continue working in the lazy stupor that Pakistani businessmen and industrialists seem to love and strive for. However, they are not wrong about one thing: the government has not been helping in all of this.

“They were very active in the first year,” says Naeem Abbas. “We were also called to Islamabad many times and told our suggestions would be considered, but nothing came of it. We felt they would listen to us, but instead we ended up with things getting worse, and now 60% of the tanneries in Pakistan are now closed with more shutting their doors soon.”

The biggest issue in the sector as of now that he points out is pending payments. With the pandemic, customers ended up demanding an increase in the tenure of pending payments. While this was a legitimate compulsion, it has left most leather manufacturers strapped for cash.

“We have given our customers the benefit of the doubt and we stand by them in their plight. But it is still a blow, and then we have the second major issue on top of that, which is freight charges. These are hurting the industry on a large scale,” Abbas explains. “Flights were shut down after the outbreak of coronavirus and freight charges rose from $2 to $5. Extra freight charges are unwilling to be borne by the customer, which the industry has to pay out of its own pocket.”

“We will have to bear this cost until passenger flights begin. At our request, the government helped us with our liquidity and our refunds and rebates were released. We were banking on this crisis being gone by Eid, which is when we needed cash the most since we buy the hides with that cash. But now our money is stuck in foreign countries.”

The government claims that it is working on resolving the issue, with Punjab Industries Minister Mian Aslam Iqbal telling Profit that the PTI government was fully aware of the importance of the leather industry. However, beyond the basic statement of reassurance, there was little that the minister had to offer.

“The business community, like any other sector, has been hit hardest by the coronavirus pandemic. It is our responsibility to solve the problems of traders and industrialists and we will fulfill this responsibility. I have also directed to formulate a plan to improve the infrastructure in the area allotted for tanneries, he said.

When asked what this plan was and whether or not it was too late by now, the minister insisted that the government is providing the best possible facilities to the industrialists. “Value addition moves the industry forward which needs more attention. The government is providing the best environment for business and providing facilities to the industrialists on priority basis,” he said.

The eid equation

Everyone has seen how big the kerfuffle over hides is after Eid-ul-Adha. Well before the Islamic festival that honours sacrifice has even begun, NGOs, government bodies, charities and political parties are all out to collect the hides of the sacrificial animals that are supposed to be given away as charity.

We have all been through it, from the catchy slogans like “Sacrifice for God, hides for Shaukat Khanum” by charity organisations to the less attractive threats of certain political parties in certain cities [yes, we are talking about the MQM in Karachi], the hides business is a free for all, since the raw product is essentially being given away for free. It is all a question of who can collect them, and how cheaply leather manufacturers can buy them.

And the leather industry waits with bated breath every year for Eid, because this is one of the reasons Pakistan’s leather is so good. Livestock reared for meat and hides is usually small, and thus gives smaller hides. The animals bought and sacrificed for Eid are bread for beauty and size, which ends up meaning that the hides are of a greater size and quality, both of which are desirable for leather production.

“The quality of the sacrificial hides is much better than the hides purchased in routine days. For example, the size of a goat’s hide purchased all year round is 4 to 4.5 square feet, while the size of a sacrificial goat’s hide ranges from 8 to 12 square feet” Afzal Hussain explains. “Similarly, in the case of cow hide, the size of the hide purchased in routine days is 25 to 27 square feet, while the size of the sacrificial animal ranges from 40 to 50 square feet.”

Afzal believed that goat sacrifice had declined in the last few years, due to the high cost of the animal. “In our country, the tendency of people to buy goats or sheep on the occasion of Eid-ul-Adha is decreasing due to high prices. People prefer cow sacrifice because it is collective.”

He estimates that the number of goats sacrificed this year will be less than the number of cows, while the leather industry will have 25% fewer hides available this year than last year. “It is a bit difficult for us to estimate the collection of hides because we do not get exact figures from any government department, but since all the NGOs or private organizations that collect hides reach us later, we can guess whether the collection this year was less or more than the previous year.”

Explaining the collection of hides and how to reach the industry, Sheikh Afzal informed that in the three days of sacrifice, large NGOs, charities or private organizations collect sacrificial hides while many such organisations also make collective sacrifices and the collected hides are delivered to leather markets across the country.

“In the leather markets, these hides are first salted and then sorted by quality wise. The hides are auctioned in these markets and anyone who wants the size and quality buys it by bidding. Another way to buy sacrificial hides is for the tanneries themselves to buy them from NGOs or charities and they sort it by themselves in terms of quality.”

The price of hides depends on the demand and supply in the market. The prices of sacrificial animal hides were high seven or eight years ago but are now very low. This situation is not only in Pakistan, but also in the international market. “Earlier, we used to buy a sacrificial goat hide for Rs800 to Rs1,000, while a cow hide cost Rs5,000. Last year, the price of cowhide was very low, while this year, cowhide will be sold in the market for Rs400 to Rs500.”

Afzal believed that for the last few years, Eid has been celebrated during the summer and rainy season and the quality of the hide has not been good because of this, which was also a minor factor in the recession that the industry saw over the past few years. “It (hide) is a perishable item and the sooner it is purchased the better. In this season, if the hides are not sorted immediately, they get damaged, while if they are not salted for twelve hours, their value becomes zero.”

“Another reason for falling prices is the slowdown in demand in the market. Earlier, the industry had orders all year round and used to buy and store hides on Eid days, but this year the situation has changed due to Covid-19. The market is currently in a state of uncertainty. The industry does not even have new export orders. The hide that used to sell for $30 to $35 in the international market is now worth only $10 to $12.”

According to the data available with his association, for the last three years, 20% to 25% of the sacrificial hides have become unusable due to negligence. He further added that the market for sacrificial hides during Eid is worth billions of rupees. “This year the market volume of sacrificial hides will be between Rs8 to Rs10 billion.”

Nadeem Abbas also agrees, saying that the purchasing power of the people will decrease significantly this year. “It is very easy to estimate how the purchasing power of the people will decrease. According to official figures, the number of cow sacrifices in the year 2018 was 3 million and in the year 2019 it decreased by only 500,000 and it was 2.5 million. In the year 2018, the number of goats sacrificed was more than five million, which had decreased to 3.5 million last year. This means that people considered it more appropriate to contribute to the sacrifice of a cow for Rs12,000 than to buy a goat.”

The PLGMEA chairman said that due to the coronavirus, there had been a clear decline in people’s purchasing power this year, and this would also be reflected in animal shopping. Add to this the weather in which Eid has come, and the overall amount of hides collected will be very low this year.

“The important thing is that even though the hides there may be fewer hides gathered, their price is very low. Cow hides were bought for Rs900 last year, which used to sell for Rs1,800 to Rs2,000. Similarly, goat hide was sold for Rs150 to Rs200 while sheep hide was sold for Rs25 to Rs30. One of the main reasons for the decline in the leather business is that the middlemen in the leather markets are not getting orders from big companies, so the leather is not as expensive as it used to be. If the hides are bought at the old rate, the cost will not be met. This year, the sacrifice rate will be reduced by 15% to 20%.”

And as he explains, there is a lot more to the treatment of these hides than meets the eye. For example, whether it is the hide of a sacrificial animal or a routine animal, there are three steps to converting it into usable leather that determine its value. One stage is the hide itself, the other stage is the chemical used on the hide and the third is the labor cost of the process. Clumsy butchers, due to their negligence, make cuts on the hide and with one cut; the A-plus hide becomes category A. While two cuts put it in B category and three cuts put it in C category. “For the common man, these seem to be small cuts, but for us, the cut hide becomes useless. Garment patterns cannot be formed on the cut hide,” he said.

While high tarriff of utility bills and duties on chemical imports, certainly have a direct impact on the cost of finished products, it is incorrect to say that sales tax on imports, is damaging the industry. The way Sales Tax system is designed, it does impact the cash flows but does not become part of the total cost, because every link of the supply chain gets adjustment of sales tax paid on input stage. The industry voice will be more powerful and effective if they focus on real issues (high cost of gas and electricity and duties on imports) and not complain about everything under the sun.

Very informative. Thank you so much for writing it in so much detail that helped me a lot in my thesis 🙂

All packages from government doe not reach the core of leather industry. The main reason this industry is not prospering is the increase in electricity and gas bills. Goverment should facilitate this industry by lowering down the utilities expenses