When speaking about Pakistan’s manufacturing sector, what with its family businesses, informal dealings and an inherited seth culture, tech is the last thing that comes to mind. We knew tech and startups were slowly taking over, with fintech, edutech, pharmatech, proptech and even agritech being introduced in Pakistan. Yet somehow, we still did not expect the old-school manufacturing sector to give into digitisation.

Then in September 2021, Ahsan Ali Khan and Taha Iqbal Teli founded Zaraye, with the mission to turn the chaotic arath marketplace into a streamlined, sophisticated virtual marketplace for raw material buyers and sellers.

Khan and Teli’s experience in the startup industry, combined with Teli’s familiarity with the manufacturing industry due to his family business, helped the co-founders not only identify gaps within the market, but also come up with a tech-based solution to the procurement problem.

Zaraye’s core business is based on the marketplace side of the manufacturing industry, approaching problems in the industry relating to procurement.

Khan told Profit, “We are inherently a source platform, we wanted to understand what our customer needs, first of all, specifically around sourcing work, and then how that affects the rest of their business.”

As a B2B startup, Zaraye started by looking at what their customers’ profit and loss structure looked like. That is how they found that about 60% to 65% of those costs were being allocated to procurement. This helped Khan and his colleagues to structure their software as a service (SaaS) offering around the marketplace. It even calls its multifunctional portal a ‘Zortal’.

The startup raised $2.1 million in April 2022, backed by venture capital firm Tiger Global, and set off on a journey of rapid growth. It secured an additional undisclosed million-dollar funding in 2022, bringing the total to $3 million. The recent funding, not disclosed earlier, came at a higher valuation and was an extension of the pre-seed round. Profit was also informed that investors, including Tiger Global, remain actively engaged and are integral parts of Zaraye’s capital table.

So, Zaraye found a modern tech-based solution to the very draconian problem of procurement. How did it achieve this?

Pakistan’s manufacturing industry and the procurement problem

To understand Zaraye’s core business model, one must take a look at the relatively orthodox industry that it is trying to disrupt.

Khan shared that the manufacturing industry in Pakistan, excluding minerals and mining, contributes around $50 billion to the documented gross domestic product, according to reports by the Pakistan Credit Rating Agency. The sector represents approximately 19% to 20% of the overall economic output in the country. The actual market size is anticipated to be significantly larger, similar to the undocumented nature of the agriculture sector. A substantial portion of the Rs 7 trillion cash flow circulates through agriculture and manufacturing.

Given the heavily cash-oriented nature of this market, estimates project the manufacturing sector’s actual size to range between $150 billion to $200 billion. So, the total number of manufacturers in Pakistan is expected to be around 300,000 to 350,000, encompassing various sizes of players.

So, why did the founders of Zaraye delve specifically into procurement of raw material within this industry?

Khan says, “Around 65% of all costs are attributed to raw materials, varying depending on the specific category. The fundamental factor influencing what is manufactured, at what cost, and subsequently at what price, revolves around the choice and pricing of raw materials. Therefore, the key question becomes whether there is a significant problem to address in this market. If a substantial problem exists in a sizable market, it presents an excellent business opportunity.”

So, the co-founders saw an opportunity in a fairly untapped market and took it.

According to Khan, there are two significant challenges. Firstly, due to considerable price volatility, the raw materials, although not commodities themselves, are inherently linked to commodities and exhibit commodity-like behaviour. For instance, polymer resin in the local market is influenced by changes in global crude oil prices, which fluctuate daily. The correlation is complex, involving factors like the dollar rate and local supply and demand. This volatility, approximately 3% to 5% influenced by these factors, is also observed in commodities like cotton yarn, tied to the U.S. cotton index, dollar rates, and local market dynamics. Prices in this market are highly dynamic, changing multiple times a day or on a daily, weekly, or occasional basis, dictated by market forces rather than fixed values.

Secondly, manufacturers typically engage with several middlemen. Khan said, “Smaller and medium-sized players lack the same level of sophistication and structured procurement processes. In a market with numerous sellers, sometimes reaching into the thousands, these manufacturers are limited to communication with a small subset, typically four, five, six, or eight middlemen.”

The core issue stems from the absence of a fixed price, allowing the market to determine daily prices. For instance, a product like plastic resin, which averages Rs 180 per pound, may be sold by different sellers at Rs 178 and Rs 179 per pound, creating a significant impact on the overall profit and loss due to its substantial contribution.

The challenge, Khan believes, comes with how manufacturers or customers can efficiently discover real-time prices without a centralised, structured source of information. He explained, “This is where Zaraye plays a crucial role. It serves as a platform enabling manufacturers to swiftly and consistently discover real-time prices, ideally securing the best price possible through its reverse bidding mechanism. Zaraye achieves this by facilitating multiple groups of suppliers to bid for the orders placed by customers, addressing the primary value problem.”

Khan highlighted two major issues stemming from the fluctuating prices of raw materials, “Firstly, the absence of fixed prices leads to daily fluctuations, impacting manufacturers facing price variances for raw materials. This affects the profit and loss due to substantial material contributions.”

He continued, “Secondly, the manufacturing industry’s prolonged working capital cycles, ranging from 45 to 60 days, sometimes over 180 days, require capital injection or financing. However, SME financing in Pakistan is only 8-9%, challenging small businesses to access formal capital. Lack of creditworthiness pushes them to the informal market, where interest rates can exceed 60% APR.”

Zaray addresses these challenges by collaborating closely with businesses to gain insights into their operations. This information helps structured financial institutions, including banks, tap into the untapped manufacturing market. This initiative provides manufacturers, especially SMEs, access to more affordable and structured loans. The goal is to address the longstanding issue of limited access to formal capital for family businesses, fostering their growth and competitiveness in the market.

Bazaar, another leading B2B ecommerce, fintech and supply chain platform, that claims to serve over 5 million businesses, launched Bazaar Industrial in early 2023. This is an offering similar to that of Zaraye, addressing the challenges in raw material procurement across various sectors like chemicals, construction, and textiles. Acting as an aggregator, Bazaar says its industrial procurement arm is also focused on providing suppliers with market insights, access to a nationwide customer base, and expert sales support. Notable suppliers like Matco and Sabic have partnered with this platform, while for buyers, Bazaar Industrial offers competitive quotes, flexible payment options, and a range of raw materials, attracting interest from major players like Loads and Diamond Paints.

Unlike others, such as Bazaar technologies, Zaraye is operating in the lower tier markets where Zaraye helps manufacturers build their credit worthiness and build their credit profiles with NBFCs and Banks in the long term. Additionally Zaraye’s business model helps manufacturers connect with multitudes of suppliers across the country in real time to curate the best possible business deal for them.

Just how is Zaraye doing this?

Khan expounded that there are essentially three avenues through which a Zaraye customer can fund their inventory. “Firstly, it can be done through our own balance sheet, where we extend credit to these customers. Alternatively, customers can secure financing through the suppliers collaborating with Zaraye, provided they deem the customers creditworthy. In this process, we actively support the Know Your Customer (KYC) procedure. The third and primary focus revolves around engaging various financial institutions (FIs), banks, and non-banking financial companies (NBFCs) to participate in extending funds to these customers. Currently, we’re working with an NBFC called InvoiceMate.”

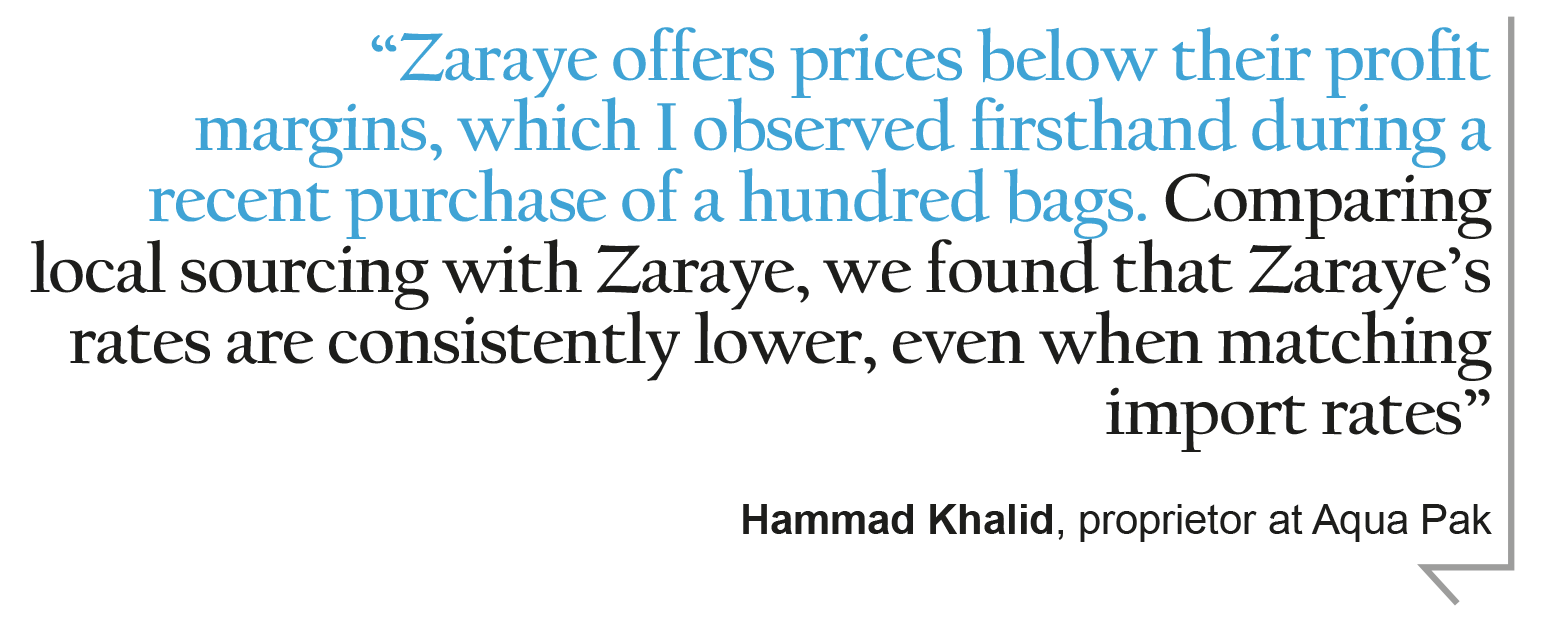

Hammad Khalid, proprietor at water accessories manufacturing company Aqua Pak, and a client of Zaraye told Profit, “In the market, rates for items experience quite a bit of fluctuation, exemplified by the pricing of pounds. For instance, if the rate for a certain commodity is 182 pounds per unit today, one might book raw material at this rate through a call. However, the challenge arises when someone else intervenes and offers a slightly higher rate, say 182.5 pounds per unit, leading to a transaction with them. This scenario, where deals are made on verbal agreements without any recorded evidence, has occurred frequently, even impacting my business. The absence of a documented record or means to contest such situations makes it challenging.”

Khalid emphasised the advantages of digitisation are notable. With digital transactions, suppliers now lock in the agreed-upon rate when an order is placed. Regardless of when the goods are collected—whether on the same day, the next day, or weeks later—the locked rate ensures consistency. This system mitigates the risk associated with market fluctuations. While a decrease in market rates represents a loss, an increase becomes a benefit as the order is secured at the initially agreed-upon rate. Khalid was confident that the digitalization of transactions brings stability and certainty to the pricing of orders, minimising potential losses for buyers.

Khalid also shared that, “Zaraye offers prices below their profit margins, which I observed firsthand during a recent purchase of a hundred bags. Comparing local sourcing with Zaraye, we found that Zaraye’s rates are consistently lower, even when matching import rates. After our first order with Zaraye, my father who founded Aqua Pak recommended sticking with Zaraye. Now we have an ongoing partnership that has involved purchasing multiple containers since June.”

What sets Zaraye apart from other ERPs?

If the offering sounds vaguely familiar, it is because it is: in Pakistan already many enterprise resource planning softwares, or ERPs, exist. So what distinguishes Zaraye from other similar product offerings in the market?

Khan explained that the primary concern revolves around the movement of money and goods within this Pakistani market. Both money and goods follow separate, non-uniform tranches. “When someone places an order for, let’s say, 100 units of product X, it doesn’t imply a fixed delivery schedule. The distribution might vary, such as 10 units every Monday for the next 10 weeks, or a split of 50, 30, and 20 units over subsequent intervals. Many sourcing platforms do not accommodate this flexibility in delivery schedules, which is the first issue,” Khan identified.

Similar global products like Zoho or Kodoo, which operate on subscription models with payments evenly divided into tranches, pose challenges for local customers. On the other hand, Zaraye’s software addresses this issue by allowing users to customise the breakdown of money recovery or receivables in any preferred denominations. Khan believes that this is a crucial insight often overlooked by most off-the-shelf SaaS offerings available in the market.

Secondly, Khan pointed out, “There exists a significant gap in local market taxation, with variations in rates for both GST and withholding tax across industries like warehousing, polymers, and textiles. This inconsistency extends to the withholding tax within each industry. The complexity intensifies during procurement for diverse industries, particularly manufacturing, compared to service or warehousing sectors. To address this, modularized and configurable taxation is crucial, allowing for breakdowns at the category level. Unfortunately, many existing products overlook this need, contributing to the incomplete digitization of manufacturing processes.”

Understanding the complexity of the textile industry, particularly for exporters who receive a GST discount and subsequent reimbursement from the Federal Board of Revenue (FBR), is essential. However, tracking the financial flow within the intricate system of payments to and from the FBR is challenging. “Our system comprehensively addresses this issue and various other taxation modules associated with a manufacturer’s interaction with the FBR, depending on their operational category. These challenges include addressing procurement, warehouse management systems, financial ledgers, and the nuanced interplay between taxation, scheduled payments, and goods delivery,” Khan concluded.

Khan informed Profit that Zaraye distinguishes itself in the competitive landscape by adopting a structured approach to creditworthiness frameworks for customers, specifically targeting the lower economic strata within the manufacturing industry. Despite being categorised as the “bottom of the pyramid,” these manufacturers possess access to technology, primarily smartphones with common apps like WhatsApp, Facebook, and TikTok.

“The ease of integrating technology stems from their existing familiarity with smartphones, allowing for a step-by-step adoption of the Zaraye app. The company initially digitised post-order processes, such as order tracking, payment tracking, and contract signing,” Khan elucidated.

He went on, “However, full app adoption faced challenges, given the market’s reliance on offline channels, emphasising the significance of relationships in this sector. Zaraye employs on-ground sales teams to manage offline operations, recognizing the ongoing transition toward complete digitization in the Pakistani market, which may take several years. The potential catalyst for a significant shift could be the eventual demonetization of Pakistan, as the market’s heavy reliance on cash currently poses barriers to full digitization due to both insufficient incentives and inherent resistance.”

Concerning the trucking industry, despite some commonalities in core operations and shared challenges in financing and fulfilment, the nuances in their problem-solving behaviours make the technologies less overlapping, shared Khan. “While there are opportunities for partnerships in financing and fulfilment, the intricacies of product design require a more nuanced approach. Despite certain overlaps in core problems, Zaraye and the trucking industry do not sufficiently align for mutual solution piggybacking,” he concluded.

Now that we have established what Zaraye does and its utility for the procurement of raw materials, let’s consider the question we posed in the beginning.

How did Zaraye breakthrough the bureaucratic systems of a legacy industry?

There is a noticeable reluctance to embrace digitisation, as it often carries connotations of change, which is generally avoided in Pakistan. How does Zaraye manage digitization and tech integration in traditional industries like textiles and construction?

Khan said, “Understanding the origin of certain rigid practices is crucial. In my perspective, some of these practices lack a solid foundation, especially when dealing with the dynamic tech sector. The tech ecosystem, being relatively new, exhibits volatility in policies, creating uncertainty about its presence and longevity in specific geographies.”

He believes that in the realm of B2B operations, like Zaraye’s engagement in purchasing services, selecting vendors becomes imperative. Stability in terms of value offerings and policies, along with the ability to consistently deliver services over an extended period, is paramount. The manufacturers in these markets have generational roots, making their livelihoods intricately tied to their established operational methods.

“The challenge arises as our approach and appearance diverge significantly from the conventional market norms—be it in terms of age, operational methodologies, communication styles, or even dress codes. Convincing these long-standing manufacturers that we are a reliable, serious player in the market demands substantial effort. Their reluctance stems from concerns about the dependability and sustainability of our business model, particularly when it involves a significant portion of their cost structure,” said Khan.

He elaborated, “In our case, steering away from heavy discounting sets us apart. While promotions and discounts are sparingly offered, mainly to first-time users, we remain steadfast in our belief that heavy discounting fosters unsustainable behaviour in the B2B sector. Businesses, operating based on profitability and cash flow optimization, may initially be enticed but are likely to shift loyalty when discounts dwindle.”

He is of the opinion that Zaraye recognises the competitive landscape and the challenges of sourcing raw materials profitably. Therefore, Zaraye’s strategy centres on creating value rather than relying on discount-driven market capture. Although this approach encountered resistance, it aligns with the scepticism prevalent in the market due to the lack of precedence for the tech industry to consistently deliver sustained value.

Khan asserted that the friction in embracing technology in certain sectors arises from factors beyond scepticism, such as limited exposure to technology beyond communication and entertainment purposes. “Overcoming this requires establishing reliability in Zaraye’s services, paving the way for a potential shift in behaviour.”

Khalid highlighted that change can be difficult but digitisation is not as unimaginable in the old school business of procurement. He emphasised that as newer generations are taking over family run businesses, they are many times also transforming these businesses to incorporate more tech and digital systems. “The younger generation is working towards digitising this platform, enhancing its appearance with the introduction of a dedicated application. With this digital shift, there is no need for manual record-keeping; transactions conducted over the phone are swiftly documented, eliminating the need for written records. Whether booking through a phone call or placing a digital order, the process remains the same. In the digital realm, orders generate PDF files, creating a comprehensive record of purchases, ensuring that all transactions are logged and easily retrievable.”

The possibility of achieving 10x growth

Khan says Zaraye has undergone remarkable expansion and diversification since April 2022. Initially centred on textiles, specifically cotton yarn, the company has broadened its operations into five distinct categories, including construction, iron steel, polymers, and timber. Originating in Karachi, Zaraye’s operational footprint now spans four cities, delivering products nationwide.

“The comprehensive textile value chain, excluding the cotton part, now involves yarn, grey fabric, and finished products. Zaraye not only aids manufacturers in procurement but also generates additional demand for them, allowing them to focus on manufacturing operations worry-free. And a significant milestone in this journey was our partnership with Daraaz, where Zaraye serves as a major vendor for Daraaz’s private label brands, emerging as the leading supplier for their apparel private labels,” Khan said.

Zaraye’s top lines also reflect growth in scale, achieving an impressive 13 to 14 times the figures from April 2022. Despite economic challenges, the company has showcased growth in profitability. Zaraye anticipates reaching net profitability or breaking even within the next 15 to 16 months.

The customer base has also witnessed substantial expansion, growing from around 300 to 400 customers to over 5000 registered buyers on the Zaraye platform. “70% of deals are conducted on credit, providing financial flexibility for buyers and bringing many into the formal backend channels. This strategic shift not only enhances our financial dynamics but also positions customers for increased business opportunities in the future,” Khan highlighted.

Can the $3 million funding and the market’s rigidity can adequately substantiate the possibility of achieving 10x growth?

Khan highlighted the dynamics in achieving 10x growth, emphasising the significance of the base size. He said, “Growing from a smaller base is relatively easier than from a larger one. The Gross Merchandise Value metric, while useful for tracking market capture, is not a comprehensive indicator of value creation, especially in B2B markets dealing with high-value orders.”

He continued to explain that in the B2B space, particularly in the raw material sector, orders’ substantial value sizes make achieving incremental growth relatively less challenging. The transition from negative to positive gross profits is a significant accomplishment. Unlike B2C platforms, B2B startups address structural problems, requiring substantial changes rather than incremental optimisations. “Our growth is driven by structural fixes, such as efficient platform movement and securing significant deadlines for customers.”

In Zaraye’s case, solving structural issues leads to aggressive upward growth, and Khan anticipates potential 10x growth in the future by addressing three to four priority structural fixes. The nature of Zaraye’s business, focusing on structural improvements rather than operational intensity, positions the startup for substantial and rapid growth in the B2B sector.

Succeed! It could be one of the most useful blogs we have ever come across on the subject. Excellent info! I’m also an expert in this topic so I can understand your effort very well. Thanks for the huge help.

This type of shows up absolutely excellent. Most of these smaller specifics are set up as well as lots of record being familiar with. I like this specific quite a lot.

This article was written by a real thinking writer without a doubt. I agree many of the with the solid points made by the writer. I’ll be back day in and day for further new updates.

I exactly got what you mean, thanks for posting. And, I am too much happy to find this website on the world of Google.

This process will be creatively actually the best option. Every single one regarding infinitesimal shows are usually designed through several traditions expertise. I would recommend the application a lot.

That’sthe reason advertising and marketing that you suitable homework in advance of crafting. It is also possible to jot down improved posting with this.

This process will be creatively actually the best option. Every single one regarding infinitesimal shows are usually designed through several traditions expertise. I would recommend the application a lot.

The article looks magnificent, but it would be beneficial if you can share more about the suchlike subjects in the future. Keep posting.

The article looks magnificent, but it would be beneficial if you can share more about the suchlike subjects in the future. Keep posting.

I got too much interesting stuff on your blog. I guess I am not the only one having all the enjoyment here! Keep up the good work.

This is often just as a fantastic articles my partner and i really actually enjoyed examining. This is simply not on a regular basis that i have got prospective to work through a concern.

I got too much interesting stuff on your blog. I guess I am not the only one having all the enjoyment here! Keep up the good work.

The article looks magnificent, but it would be beneficial if you can share more about the suchlike subjects in the future. Keep posting.

The article looks magnificent, but it would be beneficial if you can share more about the suchlike subjects in the future. Keep posting.

This process will be creatively actually the best option. Every single one regarding infinitesimal shows are usually designed through several traditions expertise. I would recommend the application a lot.

This is often just as a fantastic articles my partner and i really actually enjoyed examining. This is simply not on a regular basis that i have got prospective to work through a concern.

This unique appears to be certainly superb. These types of really small truth is created utilizing wide selection associated with skills know-how. We prefer the concept a great deal.

Their particular obtained onto your website despite the fact negotiating reputation merely several tid tad submits. Rewarding strategy for forth-coming, I am bookmarking prior to starting grab goods bottom line spgs entirely upwards.

I have not checked in here for a while as I thought it was getting boring, but the last few posts are good quality so I guess I¡¦ll add you back to my daily bloglist. You deserve it friend