“The government solution to a problem is usually as bad as the problem.” This maxim by the towering 20th century economist Milton Friedman aptly encapsulates the last 15 years of policy making by democratic governments in Pakistan. Take the recent import ban by the Pakistan Muslim League-Nawaz (PML-N) government.

The pressure on the foreign exchange reserves to save the country from a default compelled the government to think of measures to choke the outflow of dollars to stabilise foreign exchange reserves. In their ingenuity, they chose to ban imports of what were termed as ‘luxurious and non-essential goods’. From frozen food to home appliances, a blanket ban was imposed on the imports of 38 different categories of products.

The solution has turned out to be as bad as the problem – one of the categories of products for which the import ban has been put into effect is mobile phones, which has sent the industry scrambling when it was just starting to take up.

In 2020, the then Pakistan Tehreek-e-Insaf (PTI) government introduced a Mobile Devices Manufacturing Policy to boost local manufacturing of mobile phones which introduced import tariff structure that incentivised local manufacturing by importing raw materials, over importing completely built mobile phones.

“Before the 2020 Mobile Devices Manufacturing Policy, manufacturing a mobile phone in Pakistan was not a viable business,” says Aamir Allawala, CEO of Techno Pack Telecom which manufactures Infinix mobiles in Pakistan. “CBUs had low duty but the duty on the parts to assemble mobile phones was the same as CBUs. It was not a lucrative proposition to manufacture cellphones in Pakistan but the PTI government created a differential of about 15% in duty of CBUs compared to CKD and SKD parts that are imported by the industry for manufacturing,” he adds.

Imports of cellphones, just like automobiles, are carried out under three categories: they can either be imported as completely built units (CBUs) of mobile phones, semi knocked down (SKD) kits or partially assembled parts of mobile phones which would have to be assembled at the destination of import, or as complete knocked down (CKD) parts which are totally unassembled parts and have to be assembled from scratch.

Because of the policy in 2020 that reduced duties on import of raw materials as CKD or SKD parts and incentivised local assembling and manufacturing of mobile phones, within a period of one year, almost all the brands that are sold in Pakistan, are assembled in Pakistan.

The most notable and famed entry into local manufacturing of mobile phones was of Samsung which contracted its mobile manufacturing in Pakistan to Lucky Group. Samsung mobiles are now manufactured in Pakistan by Lucky Group at their plant in Karachi. Similarly, Vivo, which has huge volumes of sales in Pakistan, is now manufactured at a plant in Faisalabad which was setup by Chinese investors. OPPO has set up a plant in Lahore, Nokia has set up a plant in Pakistan, and Xiaomi is now manufactured in Pakistan at a plant set up by Airlink.

“Manufacturing is a very lucrative business globally. It’s the same here for us as well but it can only remain lucrative for as long as the government policy is aimed at keeping it lucrative. Till now, the policy from the government has been favorable for us,” says Muzaffar Piracha, CEO of Airlink Communication, which is the authorised reseller of Apple phones in Pakistan.

Except iPhone, almost all the mobile phone brands that are sold in Pakistan, are assembled and manufactured in Pakistan.

Why iPhone has not yet set up a plant? Pakistan is still a low-income country with majority of the people having limited purchasing power to afford an iPhone. The number of iPhones sold in Pakistan is too small yet for Apple to consider setting up a plant in Pakistan. According to market research by Profit and imports data, 198,869 iPhones worth $72 million were imported and sold in Pakistan last year. Compare that to 1.38 million Samsung phones worth $248 million, whose parts were imported into Pakistan, were assembled here and then sold locally in 2021.

Cumulatively, Pakistan imported $1.67 billion worth of CBUs, and SKD/CKD parts in 2020. In 2021, these imports were $1.97 billion. In 2021, according to numbers provided by the cellphone manufacturing industry, iPhone share in the market was 1.32%. Since iPhone is the only sizeable CBU import, the remaining imports were of CKD and SKD parts in 2021. On the other hand, purely local brands such as QMobile, DCode, Digit 4G, Mobile Club and Hello Tech also import all the parts for manufacturing of mobile phones.

“More than 95% of the mobilephone imports are SKD and CKD kits because all of these brands are manufacturing in Pakistan locally,” says Muhammad Naqi, the CEO and director of Premier Code which manufactures local born DCode mobile phones in Pakistan. “Samsung, OPPO, Vivo, Xiaomi, likes of Nokia and all have their own setup in Pakistan one way or the other. They have either setup plants directly or have set up plants through joint ventures,” he says.

So when the government introduced the import ban, it was only considered to be on the CBUs. Meaning that no completely built mobile phones, like iPhones, could be imported but SKD and CKD parts were considered to be not under the effect of the ban.

Since the bulk of the imports are CKD and SKD kits, the ban would not have had any significant impact on the industry, as Naqi tells us. If we do some back of the paper calculations, 95% of CKD and SKD imports of the total $1.97 billion in 2021 would only save roughly $98 million in import payments for the government – a negligible impact of the ban on import of mobile phones.

The situation, however, has now evolved towards a different direction where it seems to be threatening the entire industry which employs 30-50,000 people.

So what is going on with the mobile phone manufacturers?

Following the import ban by the PML-N government last month, on paper, the ban is on CBUs. So under the new policy, iPhone reseller in Pakistan, Airlink, can not import iPhones into Pakistan but should be able to import CKD (cmpletely knocked down kits) or SKD (semi knocked down) kits for assembling and manufacturing Xiaomi phones. Following the 2021 policy, Airlink setup a plant in Lahore to assemble and manufacture Xiaomi phones for local sales.

The manufacturers, however, are unable to import the CKD and SKD kits either. While the import ban on CBUs was overt, covertly, the government has effectively choked the imports of CKD and SKD kits as well by setting two conditions: i) the government subjected the import of these kits to a 100% cash margin and ii) the central bank now has to approve the opening of LCs (letter of credit) before any import is authorised.

The cell phone manufacturing in Pakistan is done through imported parts. All of it. A typical smartphone constitutes more than 60 parts and none of these parts are locally made. If Lucky Group plans to manufacture a Samsung smartphone in Pakistan, they have to import the parts for that smartphone from some other part of the world (say South Korea where it is headquartered). Even if a purely local brand like QMobile wants to manufacture one of their smartphones, they also have to import the parts from some other parts of the world (think China).

The central bank’s conservatism when it comes to the outflow of dollars from Pakistan is well established. For the mobile phone manufacturing industry now, the central bank approves LCs itself before commercial banks can open them for imports by cell phone manufacturers. The process currently is that the manufactures send a request to a commercial bank to open an LC. The commercial bank then asks the State Bank to approve the opening of the LC for the manufacturer. This process used to be completed expeditiously and the central bank would give the approval within one or two days. It is now taking its sweet time to approve those LCs, perhaps in a bid to stretch the imports and the dollar outflow as much as possible.

The LCs that used to be approved in a matter of two to three days, have not been approved since May 19 by the central bank, leaving the cell phone manufacturers in desperate straits. Manufacturers have also been subjected to a 100% cash margin. Commercial banks ask them to have a certain amount worth a certain percentage of the import value to be present in their accounts before opening an LC for them. Now, that percentage has been increased to 100% meaning they need to have an amount worth the complete value of the import, to be able to import. This kills the concept of working on credit, constraining the working capital of these manufacturers.

The immediate impact is on the production of mobile phones and the secondary impact, but not any less important, is on the sellers of mobile phone parts as well as the investors of the project. According to a mobile phone manufacturer who commented on the condition of anonymity, the exporters of these equipment are feeling restless because the payments to them are dependent on the opening of LCs here in Pakistan. If the SBP is not approving LCs, the exporters of these equipment are not able to receive payments for parts that they have ready to be exported, but can’t do because of the problems here.

The import of CKD or SKD kits is based on credit instead of cash, and hence the requirement of opening LCs. Now the manufacturers importing these raw materials have their own cycles based on their working capital, according to which they import the raw materials. From industry stakeholders, Profit learned that the usual import cycle is of 1-2 months, which means that a cell phone manufacturer would have, say a month or two month’s inventory of raw materials after which they would have to import. So if the SBP has not approved LCs for the last two to three weeks, the raw materials are going to deplete completely in the next 2-3 weeks. The cell phone production declines or stops, and the idle workforce gets laid off.

Layoffs are another problem that the industry faces, and legitimately uses it to show the impact the current policy is having on the industry in the presence of an effective ban on imports. And it does not stop there. Most of the brands like Samsung, OPPO, Xiaomi, and Vivo that are sold in Pakistan, are assembled and manufactured in Pakistan following the Mobile Device Manufacturing Policy. Some of the plants to manufacture some of these brands have been set up by foreign investors on their own or through a joint venture with a local partner.

For instance, Vivo plant was set up in Faisalabad SEZ and has 100% Chinese investment. OPPO plant in Lahore, too, has been set up by Chinese investors. Tecno Transission Electronics, which owns brands like Tecno, Infinix and iTel, is a joint venture between Tecno in Pakistan and China’s Transsion Holdings. The foreign investors, and even the brands that have completely contracted out their manufacturing in Pakistan to a local business group, are not going to have a good impression about investing in Pakistan.

“Vietnam is a mobile manufacturing success story. The Vietnamese government brought in Samsung in Vietnam in 2013 and set up the first mobile phone assembly plant. Today, Samsung exports $40 billion worth of mobile phones from Vietnam to the rest of the world,” says Aamir Allawala, CEO of Tecno Pack Telecom which owns Infinix brand.

“When the Vietnam mobile phones manufacturing became successful, they brought in their appliances as well. Samsung’s exports from Vietnam are roughly $60 billion now and they employ about 170,000 people. Following the Samsung success story, other brands also jumped in,” Allawala adds.

There is a case to be made that with one success story, you can attract many others to create more success stories. If you are able to attract one pigeon on the roof, others will follow too. Contrarily, with one shot, you can scare all the pigeons away. The ban may have been just be that shot.

The squabbles

The situation is painful for mobile phone manufacturers. Some of them have laid off staff they trained only like a little over a year ago when the new policy was introduced, citing that they can not afford their expensive payrolls in this situation. Manufacturers are scaling back, and have warned of a complete shutdown in the coming week if the situation is not salvaged. And in an attempt to salvage the situation, they wrote a letter to Finance Minister Miftah Ismail to allow CKD and SKD kit imports (effectively banned because of LC approvals by the State Bank and 100% cash margin requirement) for cell phones less than $100 in value.

The letter, written by the Mobile Phones Manufacturers Association (MPMA) claims that 70% of the mobile phones manufactured in Pakistan are below $100, and their import bill is only 30% of the total import value of mobile phones. Hence, allowing this category of cellphones which forms the bulk of the market but consumes less than half of the foreign exchange, would not have a substantial impact on forex reserves.

Is the measure prudent? The Mobile Phones Manufacturers and Importers Association (MPIMA) doesn’t think so. The industry has two associations, both of which claim to be the official representatives of the industry. The MPIMA has also sent a letter to Miftah Ismail with the same suggestions to ask the SBP to open LCs without any discrimiation of the value of the cell phones, withdraw cash margin requirements and give an R&D (research and development) allowance to the industry to help them export mobile phones.

MPIMA does not agree with the MPMA’s suggestion of allowing imports for cell phones worth less than $100, and accuses it of pursuing a vested interest. In its letter to the finance minister, the MPIMA even tried to discredit the MPMA by calling it a ‘self-claimed and unregistered association’ which only has 20% members from the industry and is, therefore, not the true representative of the industry. Whereas MPIMA claims to have members that represent 80% share of the mobile manufacturing market and has members such as Lucky Group with the Samsung brand, OPPO, Vivo and Xiaomi – four of the biggest mobile phone brands in Pakistan.

MPIMA has members that are big brands like Airlink, which manufactures Xiaomi mobiles. Airlink Chief Executive Officer (CEO) Muzaffar Hayat Piracha serves as the chairman of the MPIMA. On the other hand, MPMA is headed by Abdul Rehman of G’Five Mobile and has Aamir Allawala of Tecno Pack as the senior vice chairman. MPMA claims to have 26 manufacturers as members of the association. The total number of mobile phone manufacturers in Pakistan are estimated to be around 35.

Big brands like Airlink have a stake in the market with the iPhone brand, which is currently under complete ban because it is imported as a CBU. iPhone is worth over $100 for sure so if MPMA’s suggestion gets through, most of the manufacturers get to import (since 70% of the cellphones are worth less than $100 as claimed by MPMA), except high value phones such as iPhone, and save many jobs in the process. So instead, MPIMA has asked for the lifting of ban for everyone and has pitched to the ministry that if imports are lifted, they would be able to export as well.

The suggestion of exports might not be so prudent however because the decision to export from Pakistan will be taken by Samsung in Korea or Xiaomi in China. Even if they allow exports, more raw materials would have to imported to manufacture mobile phones for exports. The net effect on forex reserves because of exports would be less. The MPMA, too is wary that MPIMA is seeking its own interest. And that its better to get something out from the government even if it is at the expense of notable manufacturers.

The distrust between the two associations is discernible and is certainly not good for the industry that is still trying to get onto its feet and claims to be promising for the country.

The eventual aim of the 2020 policy is to boost the ‘Made in Pakistan’ brand. “When local assembling and manufacturing takes up, localisation will start happening. The parts used in the manufacturing of mobile phones that are being imported now will be started to be produced locally,” says Muhammad Naqi.

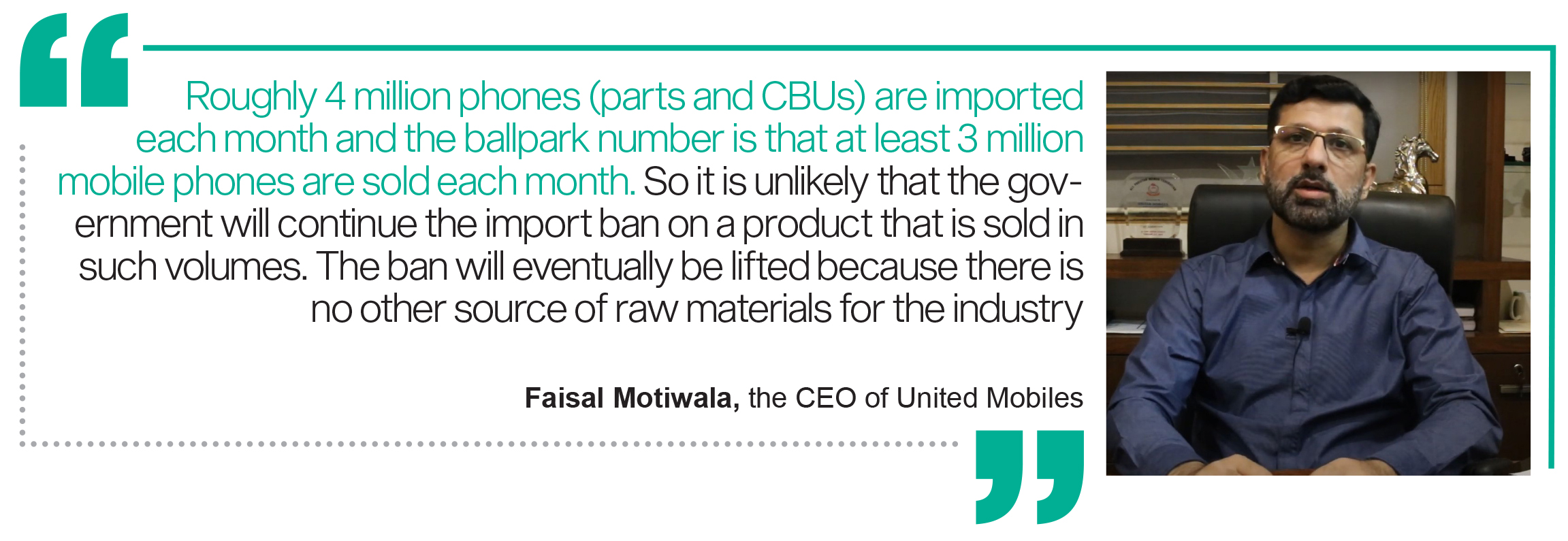

For the time being, the problems related to imports persist. Faisal Motiwala, the CEO of United Mobiles, one of the oldest and largest mobile phones distributor in Pakistan says, “Roughly 4 million phones (parts and CBUs) are imported each month and the ballpark number is that at least 3 million mobile phones are sold each month. So it is unlikely that the government will continue the import ban on a product that is sold in such volumes. The ban will eventually be lifted because there is no other source of raw materials for the industry. We are quite hopeful that the problems regarding the LCs are going to be solved by the end of this month.”

However, on June 17, media reports surfaced claiming that the State Bank had allowed the opening of LCs for the import of mobile parts. CEO of a mobile phone manufacturing company also told Profit that the central bank had allowed opening of LCs for imports of cell phone parts.

The SBP had not approved any LCs since May 19, 2022. And on June 17, the central bank approved only a handful of LCs of some manufacturers. There is no clarity yet that the central bank would resume giving approvals for LCs for all manufacturers, and it would do it, like before, in a matter of days.

If the SBP has given approval to some manufacturers right now, its surmising that imports will begin in full swing. According to the CEO of a mobile manufacturing company, since the entire industry is getting affected, the SBP might set up some quotas for each manufacturer and approve LCs based on that quota, so that all manufacturers are able to keep the business running, albeit at lower scale.

When would the imports resume is unsure, but it will certainly happen. What is also certain is that the industry needs to get its act together to achieve the goals envisaged in the policy that led to the creation of this industry.

[Editor’s note: An earlier version of this article identified Airlink as a distributor of Apple phones in Pakistan. The error is regretted.]

Very nice article written

Outstanding article

I dеfinitely loved every little bit of it and I have you book marked too check .

온라인 카지노

j9korea.com

Here are 5 problems you run into when using an iSpring crack or an iSpring keygen. Risk 1. Software viruses. Pirated activators always contain viruses