- ‘Increased govt levies are encouraging unscrupulous elements to import under-invoiced Iranian cement’

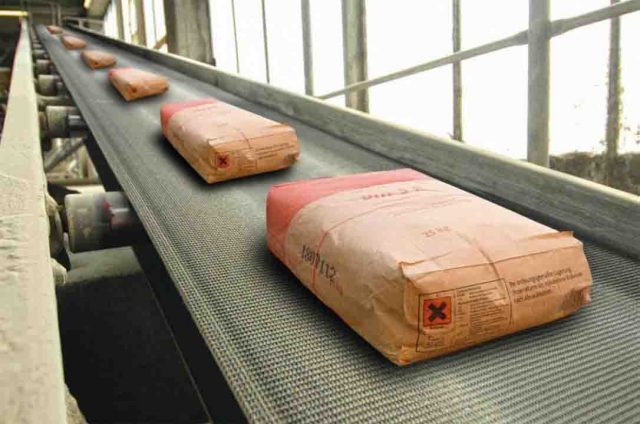

LAHORE: Pakistan has been losing a major share of its market in Afghanistan to Iranian cement, as high energy cost has made the cement production more expensive.

Rejecting the massive increase in gas and electricity rates, which had been notified for implementation from July under an agreement with the International Monetary Fund, the industry stakeholders said the cost of doing business has been increasing continuously in Pakistan, leading to a constant decline in exports and a hike in the trade deficit.

The government had announced an increase in electricity prices by Rs1.50 per unit and gas prices by up to 168.36pc last month.

Industry experts lamented that in less than 40 days after increasing gas tariff by up to 200 per cent, the government has now hiked minimum gas charges by 39pc for almost all consumer categories.

As per details, minimum gas charges are payable by every consumer irrespective of consumption levels. This means that even closed premises having gas connections but zero consumption are also required to pay this charge. The minimum rates for registered manufacturers or exporters belonging to different sectors, including textile, jute, carpets, leather, sports and surgical goods, were increased by 38.6pc, from Rs20,232 to Rs28,060 per month.

Experts said the cement industry was contributing positively to the national exports, besides providing jobs to thousands of workers. “But the government must reduce the cost of doing business in order to promote industrialization.”

They said that the devaluation of Pakistani Rupee against the US Dollar was already hurting the growth of the cement industry.

“The cost of electricity and gas in Pakistan is already the highest in the region while additional duties on coal imports have nullified the lower value of coal in the global markets. On the domestic front, high government levies have encouraged some unscrupulous elements to import under-invoiced Iranian cement, resulting in a drop in the domestic sale,” they highlighted.

According to experts, the exports were down not only because of high cost of doing business but also due to the lax attitude of the regulators who were ignoring the malpractices in imports.

The cement industry stakeholders urged the government to increase the custom duty on import of clinker in order to support the local manufacturers, besides reducing the cost of doing business in the country to encourage local sales.